Cuplock Scaffolding

Bharat Ispat Udyog is a leading Cuplock Scaffolding manufacturer. That processed for reliability, easily manageable. It is able to adapt to various building maintenance and constructional works. They are perfect figure of high-quality steel and specified design. They are the right combination of special locking and safety standards. Special features like easy installation, heavy load bearing capability and quick locking system make our vertical scaffolding a right solution for all type of construction based projects. They are time & cost Saving for your Building Maintenance & construction projects. It also offers quality work.

Features & Advantages:

- Very Easy To install & Dismantle

- Heavy Load Bearing Capability

- Time & Labor Cost Savings

- Accurate Tight Components

- Lower Maintenance cost

- Quick / Speedy / Solid Erection

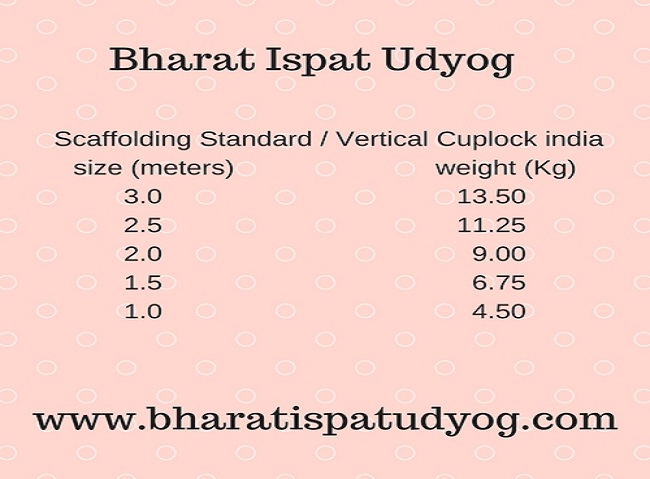

Cuplock Scaffolding Specifications

Cuplock Scaffolding System specifications manufactured from 48.3-48.5mm O.D. tubing. They have cup joints at 500mm intervals. The captive mobile top cups are designed to endure demanding site handling and welded bottom cups made of high-grade steel. Integral spigots are provided at the top of just about every benchmark for making vertical connections. The spigots Pins as well as the base of every ordinary incorporate 11/16mm Dia. Holes to enable utilisation of locking pins to join specifications exactly where necessary.

How to install Cuplock Scaffolding

Step-1

Choose a stable foundation on which to build and place your scaffold. Obtain mud sills or pedestal plates to install the scaffolding to earn the footing additional steady. One of the main factors this is to truly have the scaffolding flat and onto ground that is secure. If you’re on the unlevel earth, you then my desire to dig down to create the dirt amount in virtually any high corner. Additionally, utilize the adjusting screws onto your scaffolding to a degree the arrangement. If the top is really on the drastic incline, obtain leg extensions.

Step-2 Assemble the scaffolding framework.

Set out the endings of this scaffolding. Lift one ending piece, and then join the cross ribbon. The end with this brace needs to encourage the ending section while you lift the final part and join its top crossover ribbon. The ends of their cross-braces to the bottom of the different ending framework.

Step-3 Make sure that the scaffold is secure.

Transfer the structure to your desired position, and be sure it is flat and safe.

Step-4 Inspect the scaffolding for guaranteed safety.

Thoroughly examine the scaffolding installation to be sure all pieces protected. Reinspecting the scaffold system each time you depart the site and go back to it to make sure it is still secure.

Get Your Free Quote